At MG Print + Displays, our philosophy is to have all our capabilities in-house and under one roof. From our research and development to printing, manufacturing, production, finishing, and logistics, these steps are driven by our proprietary ERP system for accuracy and fast turnaround. Our products are developed and tested by us, allowing us to work with your designs on custom projects, even supplying installation or supervision.

Printing

Our robust large format printing department can handle your biggest print projects. With state-of-the-art UV and dye sublimation printers and transfer technology, we offer quality, consistency, and fast turnaround.

UV Printing

Our direct-to-substrate UV printing capabilities offer yet another versatile solution to our clients, allowing high-quality photorealistic printing on a very wide range of products, both flexible and rigid.

Dye Sublimation Printing

Providing our clients with the highest quality SEG prints and large format prints up to 10.5' wide, MG Print + Displays employs dye sublimation printing - the process of using heat to transfer the utmost dye to our polyester fabric as it can hold. This method ensures that the colors are vibrant and long-lasting.

Transfer

Heat transfer is the process of using heat to transfer the utmost dye to the fabric as it can hold. This method ensures that the colours are vibrant and long-lasting.

Pre-Press

The creative and professional design department is equipped with the latest resources and graphic applications to prepare your files for large-format printing. By matching your brands' colors and creating precise color profiles, we guarantee consistency throughout your production run and campaigns. We adjust your profiles depending on the CCT and lumen output of your lightboxes.

Finishing

Employing a wide range of the most advanced laser cutting and finishing equipment on the market allows us extremely accurate cutting and finishing on materials such as fabrics, textiles, wood, acrylics, and more.

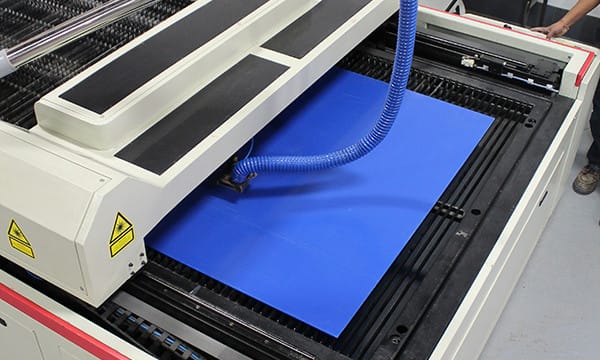

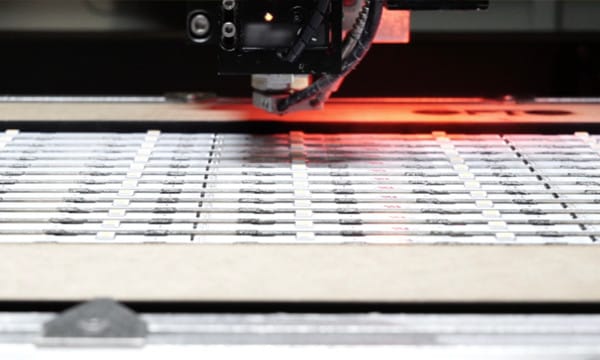

Fabric Laser Cutting

Designed for wide textile rolls, and automatic and continuous cutting, our laser cutting machines deliver high precision, sealed edges and cut quality at the fastest cutting speeds.

SEG & Overlock Sewing

Our in-house sewing facility works through the use of SEG (Silicone Edge Graphics) or interlocking stitching to ensure professional quality finishing.

Digital Cutting

Our static and oscillating knife cutters are designed to provide clean cut, kiss cut, angle cut with maximum performance on cutting operations for standard or organic shapes on varied materials. With our MMS system, each print, banner, sticker or sign is trimmed to the specific dimension of your projects for a perfect fit and continuous flow from printer to cutter.

Grommets

Grommets allow for easy installation for a wide range of products and applications for commercial, and industrial signage. Our rapid grommet press is capable of attaching grommets in a wide range of fabrics and materials.

Lamination

Lamination adds a layer of protection to finished prints. The glossy or matte surfaces help create a distinguished product. We offer both hot and cold lamination. Cold lamination is perfect for vinyl-based media finishing and intended for external use such as banners or vehicle wraps. Hot lamination is more durable and suited for acrylic, glass and metal finishing.

Paint Shop

Our paint shop is yet another value-added service that MG Print + Displays provides. Advanced techniques and premium materials allow us to control all aspects of our production process.

Extruded Aluminum

Our aluminum department, with the assistance of high-tech machinery, designs and shapes precise custom extruded aluminum, making sure our projects meet your specific requirements.

Meter Cutting

Cutting our aluminum profiles with our top-of-the-line meter saw renders outstanding cutting quality, clean cut edges without dust formation and eliminates burrs. Projects are quickly cut to your specifications.

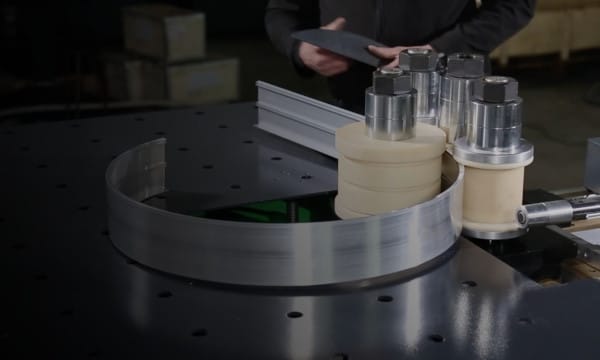

Extruded Aluminim Bending

Our bending process for extruded aluminum is precise, giving your design flexibility to create almost any shape with the possibility of complex geometries.

CNC Milling

Our CNC Milling for extruded profiles creates precise milling and matches the alignment from profile to profile.

Metal Works

Our in-house metal shop incorporates a wide variety of equipment for projects utilizing metals. From cutting, forming, bending, and welding to milling and machining, we have state-of-the-art tools to get the job done promptly and efficiently.

Laser Cutting

Our high-precision metal laser cutter creates custom sheet metal parts in various materials. Extremely accurate, we deliver clean cuts with minimal levels of slag.

Bending

Our press brake bends complex parts with high precision. We bend all kinds of sheet metal from thin to thick. Based on the design deliver custom metal fabrication with a quick turnaround.

Welding

Our team delivers high-quality metal welding. From MIG and TIG to laser welding and spot welding, supporting your design with quality finishing.

Channel Letter CNC Bending

Delivering cost-effective quality channel letters, our CNC bender manufactures front-lit, halo, open face, and front/reverse-lit channel lettering.

CNC Milling & Lathe

We support specific detailed projects by manufacturing custom parts to your design requirements.

Acrylic

Our laser cutters and CNC routers make your acrylic projects attractive, clean, and ready to assemble.

Acrylic Laser Cutting

Custom laser cutting is one of MG's processes for precision cutting, clean edges and mirror finishes on different thicknesses of acrylic.

CNC Router

MG's CNC routing machines cut and engrave many types of materials. Like acrylics, one of the most popular materials for sign making. We also engrave our acrylic panels for use in our edgelit lightboxes.

Millwork

MG offers a fully equipped woodworking shop with skilled craftsmen adding new dimensions to your projects. From simple design elements, wood-cladding of frames, cabinetry and fixtures to custom millwork, we deliver quality and functional solutions for your specific design needs.

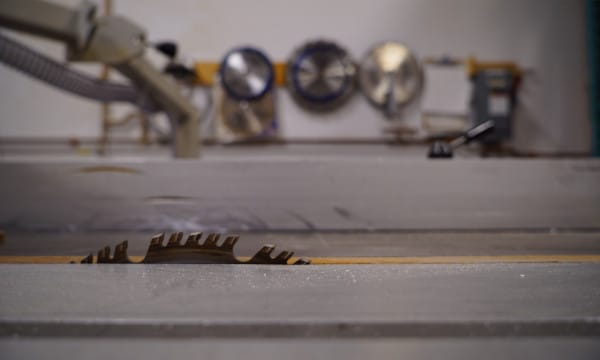

Table Saw

Accurate and precise cross cuts and ripping cuts are attainable with our high-quality table saw. Also used for the assembly of our shipping palettes.

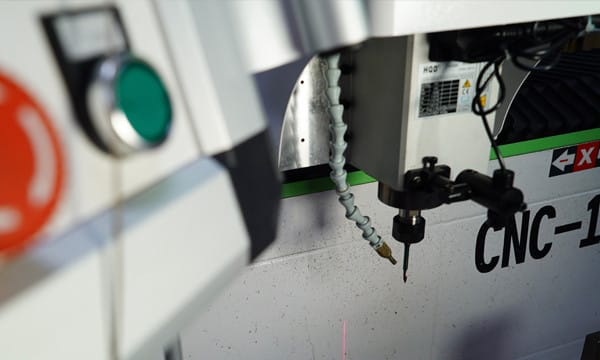

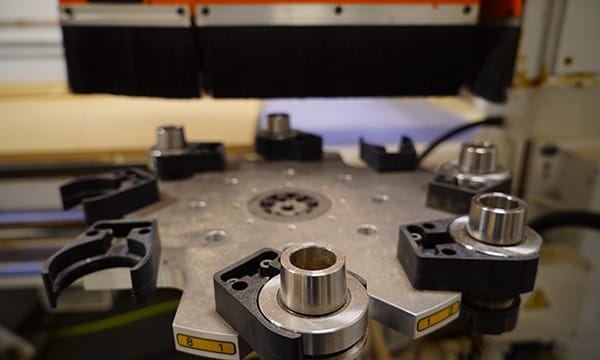

CNC Engraver

Our four-axis CNC operates with CAD files for precise engraving.

Edge Bander

Our edge bander allows us to bond an edge banding to substrates, triming the leading and trailing edges, along with the top and bottom, flush with the substrate.

Quality Assurance

All our efforts ensure that our products delivered to our clients meet the highest performance, design, reliability, and maintainability expectations.

Testing

With our 28 years of experience, we achieve our premium standards of efficiency and efficacy with an intensive quality control process. We continuously test, innovate and improve existing products to ensure we provide our clients with the exact products that fit their needs.

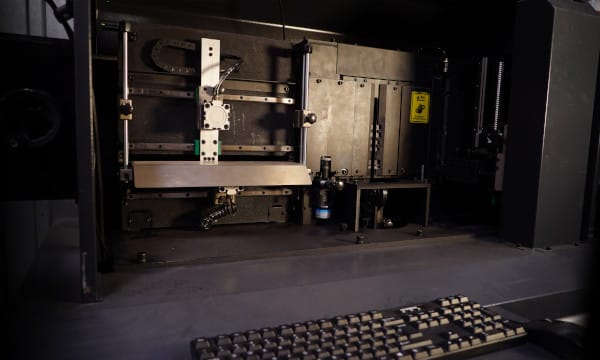

R&D and Design

Constantly researching and developing new products and updating existing ones, our goal is to provide our clients with quality solutions. With our team of mechanical and electronic engineers, we maintain the highest quality products.

Laboratory

Staying on the leading edge of technology, we operate and maintain an advanced laboratory allowing us to study all of the components that go into our manufacturing process. This technology enables us to excessively test our components for extreme outdoor conditions according to the highest standards.

Inventory

We maintain a vast inventory of quality parts and materials, enabling us to maintain competitive production and selling costs. With our large inventory, we guarantee that your projects will be delivered on time.

Lighting

The core for each of our lighting projects is our own patented Tension LED System. The TLS offers four lighting engines, Astra, Sola, Aurora and Vega to fit the requirements of your lighting project.

Lighting Production

We designed and built our very own production equipment to manufacture the TLS which allows us full control of the pitch between LED boards and the lumen output, which permits us to VE your project and match your budget.

IP65

The coating process on our LED boards for our outdoor projects delivers a final product with an ingress protection rating of 65.

Client Relations

Customer Service

Our proprietary MMS system allows our clients to track their project details every step of the way. Our sales, graphic, production, logistics, tech support departments and installation network accompany our clients through every phase of their projects with one-on-one support and services giving our clients peace of mind with their projects.

Quoting

Our highly trained team utilizes a rapid quoting system derived from our ERP to provide your quotes. Having all of our production capabilities in-house, we offer competitive pricing by keeping our costs low.

Logistics

Our logistics department is ready to handle anything from the simplest shipments to large, drop-ship rollouts. We even designed our packaging to safely flat pack our frames and lighting. Whether shipping locally, nationally or internationally, our team is experienced in delivering your products worry-free and on time.

Supervision & Installation

Our network of trained installers is available for cost-saving installation supervision along with your general contractor or complete installation of lightboxes, replacement seg banners, or complex lighting installations including controls.